Sonya and Neil Newnham are a resilient team. They have weathered various crises and bounced back. In May 2008, they bought Belco Custom Trailers - a marine and camper trailer business in Brendale. This was just before the Global Financial Crisis (GFC) really hit Australia. By December of 2008, they were about to go bust.

The GFC impacted on the businesses related to the leisure industry. About 30 of their customers - boating and camping dealers in Queensland - closed down. Sonya and Neil sought help from several sources, including the bank, but to no avail. Finally, their accountant came up with the best advice: “Do something different.”

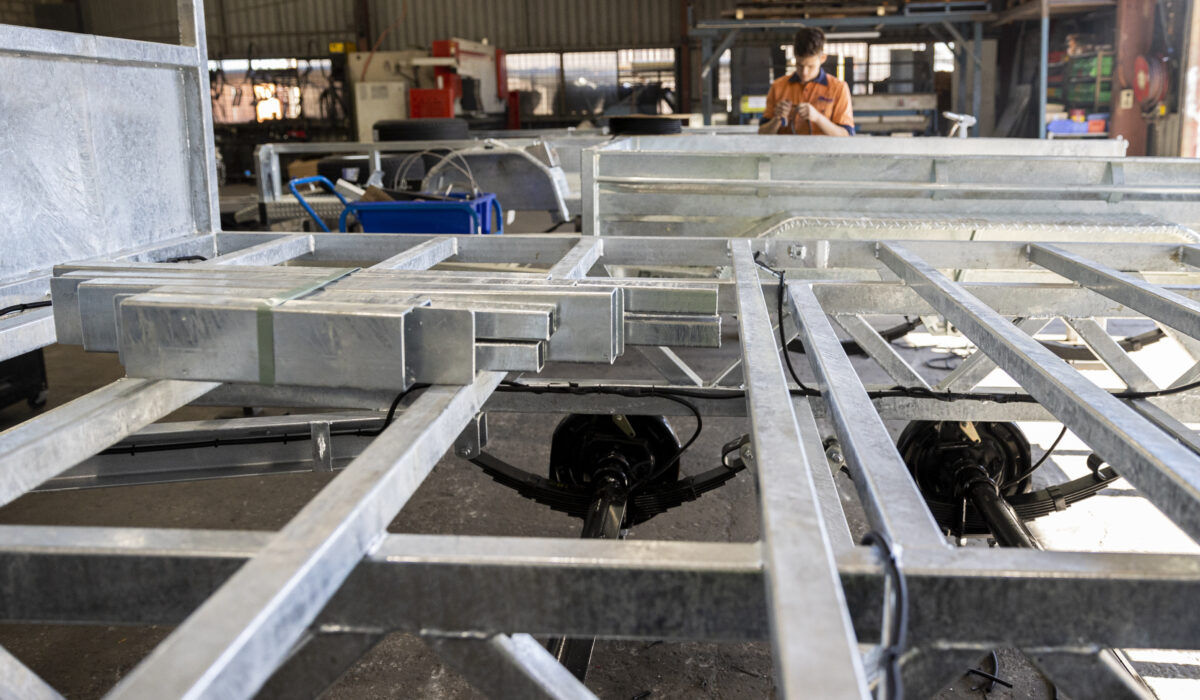

Sonya and Neil figured the public sector would still have finance in the crisis and so turned their focus to repairs and maintenance of trailers for government infrastructure. Sonya said they mainly targeted regional councils and their business successfully “did $22,000 worth of repairs in January of 2009”. Aside from trailer repairs and maintenance, the business now manufactures custom trailers for various industries, including council fleets, plant and commercial construction, rural industries, renewable energy industries, the recreation industry and home users.

A rocky road

Belco Trailers clawed their way back from the GFC baptism of fire but had many ups and downs along the way. For example, Sonya explained that: “after a few good years in row,” they decided to pull back a little and employ a manager. Unfortunately, after employing ineffective managers on two separate occasions the business suffered major setbacks. The business experienced such a bad year in 2015 following the second attempt under a new manager that Neil said: “we thought we were going to have to pack up and sell.”

Sonya and Neil stepped back up again into managing the business themselves and it is going from strength to strength. They credit their ability to re-build the business to lessons learned “through trial and error, and a lot of learning from mentors”. Two years ago, they won a Queensland Government Business Growth Fund grant for specialised mentorship services. The mentors looked at the business and identified areas for improvement that Belco subsequently addressed.

"They credit their ability to re-build the business to lessons learned “through trial and error, and a lot of learning from mentors”.

COVID impacts

The negative impacts on the business from the COVID crisis have been relatively minor. They have had some issues getting parts, such as spring bolts, clearance lights, and some galvanised steel. Belco Trailers have always specified Australian steel in their orders. However, during COVID the demand for Australian-made steel was exceeding the supply.

The business somewhat benefitted from the effects of the pandemic. “We’ve been extremely lucky”, Sonya said. There has been more of a push towards buying Australian-made products, as well as using local manufacturers and businesses.

Neil said the COVID government incentives have also created more spending in their industry. For example, “the $150,000 tax write-off and the $10,000 that people could take from their superannuation…we found that people were coming in to buy trailers with that money”.

Most of Belco’s customers are commercial businesses and government authorities. Sonya and Neil note that these customers have made an effort to particularly support local SMEs in this crisis. Local government authorities, such as Moreton Bay Regional Council, have significantly improved payment terms, reducing the time to pay invoices from the usual 30 days to 7 to 14 days: “some even immediately, so that makes a huge difference to cash flow,” said Sonya.

Future

The firm is in the process of restructuring staff roles to optimise the team operations. They have also been mentoring one of their talented employees to take on the general manager position: “He now knows the trials and tribulations of each area of the business”, Sonya said.

Belco are investing $100,000 in a fibre laser cutter, which is anticipated to change the way they operate. Neil said: “This machine will make operations far more efficient and diversify our products”. They expect the machine to help minimise errors and waste, “and open new avenues of business – a whole new industry,” Neil says.